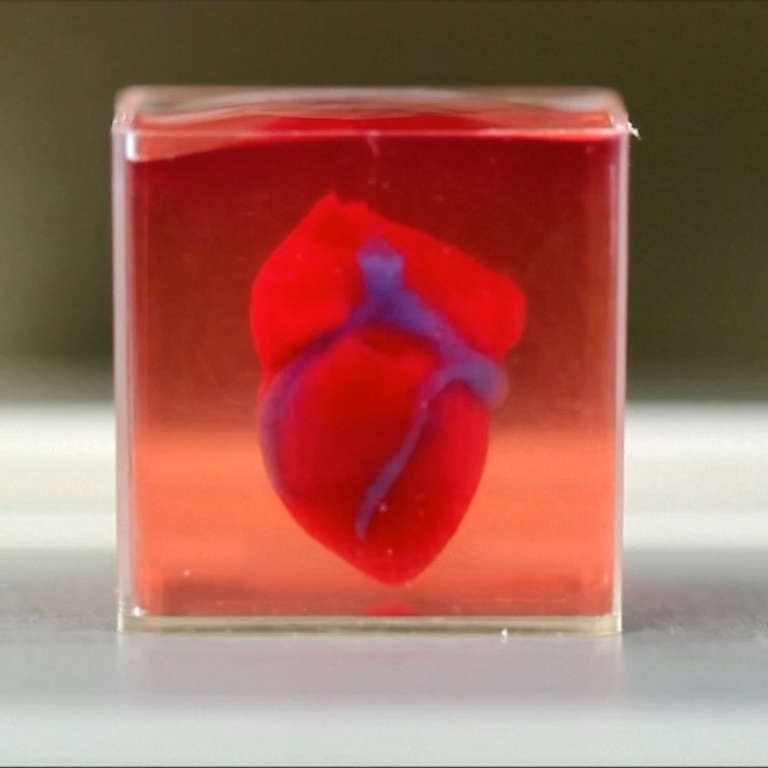

Researchers at Carnegie Mellon University have developed a new bioprinting technique allowing the 3D bioprinting of tissue scaffolds based on collagen. The innovation is an important step towards 3D printing the first full-sized human heart.

Massive Need For 3D Printed Hearts

In the United States alone there are 4,000 patients waiting for a heart transplants, with millions others throughout the world not qualifying for a waitlist. Though still in its very early stages, 3D printing a fully functioning human heart could potentially save millions of lives.

With the new method proposed by the research team, printing a full-size human heart is a few important steps closer.

Until now, it has been impossible to replicate the complex extracellular matrix (ECM) providing the structural and biochemical basis of normal cell function. With the new technique, called Freeform Reversible Embedding of Suspended Hydrogels (FRESH), this obstacle may finally be overcome.

“What we’ve shown is that we can print pieces of the heart out of cells and collagen into parts that truly function, like a heart valve or a small beating ventricle,” says Adam Feinberg, a professor of biomedical engineering (BME) and materials science and engineering at Carnegie Mellon University. “By using MRI data of a human heart, we were able to accurately reproduce patient-specific anatomical structure and 3D bioprint collagen and human heart cells.”

Collagen Printing Made Easy

At the core of this technique is collagen printing – a notoriously difficult process due to the liquid form of the substance.

Andrew Hudson, a BME Ph.D. student and co-first author on the paper, explains: “Collagen is an extremely desirable biomaterial to 3D print with because it makes up literally every single tissue in your body. What makes it so hard to 3D print, however, is that it starts out as a fluid — so if you try to print this in air it just forms a puddle on your build platform. So we’ve developed a technique that prevents it from deforming.”

The new technique allows collagen to be layered within a support gel bath, which lets it solidify before being removed from the bath. After the print is complete, the gel can be easily removed by heating it to body temperature, thus leaving the printed structure intact.

The method can be extended to other soft gels including hyaluronic acid and fibrin, making it a very versatile tissue engineering platform.

Open Source Design

The researchers have also developed open-source designs offering almost anyone access to low-cost, high-quality 3D bioprinters.

While bringing 3D human heart printing closer, the technology does not yet allow by itself the printing of a fully-functioning human heart.

“It is important to understand that there are many years of research yet to be done,” says Feinberg, “but there should still be excitement that we’re making real progress towards engineering functional human tissues and organs, and this paper is one step along that path.”